Arch Doors – A Modern Take

In the world of architecture and design, certain elements echo the essence of eras gone by while resonating with modern aesthetics. One such element is the arch (or arched) door. At Solwest, we have the skills and machinery to craft these doors, combining age-old design principles with contemporary manufacturing techniques.

Timeless Appeal

Arch doors have always been an emblem of architectural sophistication. Their distinct curve stands as a testament to a design language that bridges the gap between history and the contemporary. This shape creates entrances that are not just functional, but also visually exciting.

Why opt for an arch door?

- Historical Reverence: If you’re looking to capture the charm and nostalgia of an older home, an arch door can transport you back in time, imbuing your space with a sense of heritage.

- Modern Aesthetics: For those charting out designs for new builds, arch doors can offer a fresh, yet timeless look, blending seamlessly with modern architectural themes.

- Versatile Conversions: Already have a square door opening and thinking of a renovation? Arch doors can be the transformative element you’re seeking.

Finishes

At Solwest, we understand that every space has its unique character. This is why we offer a range of finish variations to match your vision:

- Ready for Painting: For those who want a door that aligns perfectly with their colour palette, we provide doors primed and ready for painting.

- Timber Veneer Finishes: If a more organic, natural look is what you’re after, our timber veneer finishes showcase the inherent beauty of wood grains, making each door unique.

Design Choices

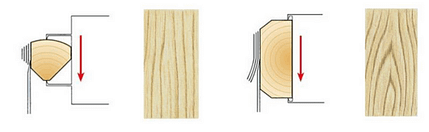

Beyond the basic structure, the devil is in the details. Depending on your aesthetic preference, we offer:

- Flush Look: A sleek, uninterrupted surface that exudes modern simplicity.

- Infil and Rebated Designs: Add depth and dimension to your door. Choose from glass infills for a touch of transparency and light, or timber for a more solid, classic appearance.

Precision

To ensure that every door fits perfectly into your space, we lean on our 5-axis CNC machine. This technology aids our carpenters in tailoring each door to the exact size and specifications required, ensuring a seamless fit and impeccable finish.

We are more than just a manufacturer; we’re a team dedicated to bringing architectural visions to life. Whether you’re renovating an older home or constructing a new one with its own story to tell, we can build you a custom arch door for your space! Contact us today for a quote by emailing sales@solwest.com.au