Timber Veneer Explained

When it comes to custom doors, veneers and laminates are an excellent choice for achieving a unique and high-end look. At Solwest, we work with a range of well-renowned veneer and laminate brands such as Briggs, Ventech, Elton Group, Fethers, Polytec, Laminex, Nikpol to offer a variety of options for our customers to choose from. In this post, we’ll explore the different kinds of veneers available for our custom doors.

- Timber Veneer: Timber veneer is the most popular choice for custom doors. It is made by slicing thin sheets of wood (~0.6mm) from a log and then gluing them onto a substrate (the substrate could be MDF or Ply). Timber veneers can be sourced from a range of species, such as Oak, Walnut, Teak, Mahogany, and many others. It can be supplied in raw form or pre-finished. Pre-finished veneer is already stained, sealed, and ready to use, saving time and effort during the installation process.

How is it made?

To make a veneer, a wood log is sliced extremely thin (0.6mm) on a machine called a slicer. These slices, known as ‘leaves’, come in various widths so are joined together to make consistent sheets or ‘layons’. These sheets are what are then glued onto our doors to produce our custom doors.

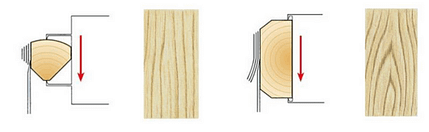

You can produce all different styles of veneers from the same log depending on how it is cut. A quarter-cut veneer (pictured left), will result in a linear grain whereas a crown cut (pictured right) will produce a ‘v’ shaped grain. This is just one variable of many that can dictate the style of natural timber veneer you would like.

- Reconstituted Veneer: Reconstituted veneer is a man-made product that replicates the look of natural timber veneer. It is made by taking thin layers of real timber and then processing them to create a new product with a unique grain and color. Reconstituted veneer offers a consistent and uniform look, making it ideal for large projects where consistency is important.

- Dyed Veneer: Dyed veneer is created by staining natural timber veneer with a specific color. It can be a cost-effective alternative to natural timber veneer, as it can be sourced from cheaper species and then stained to match the desired look. Dyed veneer can be used to create a range of colors, from bold and vibrant to more subtle and natural hues.

- Textured Veneer: Textured veneer is a type of veneer that has been embossed or textured to create a unique look and feel. This can include patterns, grooves, or even three-dimensional designs. Textured veneer is a great choice for adding interest and depth to a door design.

- Laminate: Laminate, or Low Pressure Melamine, is a man-made material that consists of layers of paper or fabric that have been impregnated with resin and then bonded to MDF or a particle board sheet under heat and pressure. It is available in a range of colors and finishes, including woodgrain and solid colors. Laminate is a durable and cost-effective option that is easy to clean and maintain.

Technology advances have greatly enhanced the quality of laminates, enabling them to replicate genuine wood and stone with outstanding precision and sophistication, all at a fraction of the cost. This remarkable progress has not only maintained the stylish appearance of laminates, but has also ensured their functionality.

At Solwest, we work closely with architects and builders to help them choose the perfect veneer or laminate for their custom doors. We understand that every project is unique, and we pride ourselves on offering a wide range of options to suit every design aesthetic and budget. Our team of experienced craftsmen ensures that every custom door we create is of the highest quality, and we take pride in our attention to detail and commitment to customer satisfaction.